Online

Attention

TOP

1、8½ GP/GC/GZ series engineering pieces main models and recommended use of strata and installation dimensions:

Type | Apply formation | Installation dimensions | |

The base facing outwards is higher than the outer diameter of the barrel wall(H) | The roller base facing inward is higher than the outer diameter of the barrel wall(H) | ||

8 1/2 GP527 | Compressive strength <50MPa, soft strata, such as salt rock, schist, anhydrite, sandstone, siltstone, soft limestone, etc. | H=(D-d)/2-32 | H=(D-d)/2-10 |

8 1/2 GP537 | Compressive strength 50 -- 120MPa, medium hard strata, such as sandstone, SLATE, shale, limestone, etc. | H=(D-d)/2-29 | H=(D-d)/2-11 |

8 1/2 GP617 | Compressive strength 120-190mpa, hard strata, such as quartzite, basalt, gabbro, limestone, dolomite and so on. | H=(D-d)/2-32 | H=(D-d)/2-10 |

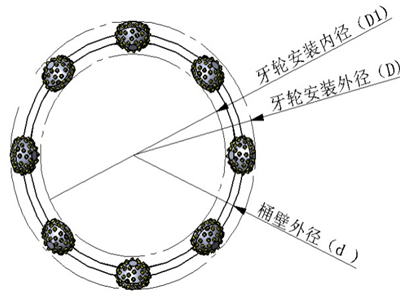

Note: 1. See attached Figure 1 for calculation formula codes in the table;

2、The engineering sheet models not listed in the table can be designed and manufactured according to the actual requirements of users.

2、Installation method:

1.Keep 300~400mm distance between the blades (the long distance between the jaws). (Recommended installation quantity: 8 pieces of 0.8 meter pile, 8 pieces of 1 meter pile, 10 pieces of 1.2 meter pile. 1.5m pile with 12 pieces) see Figure 1 for specific diameter control.

2. Installation using positive and reverse interval installation.

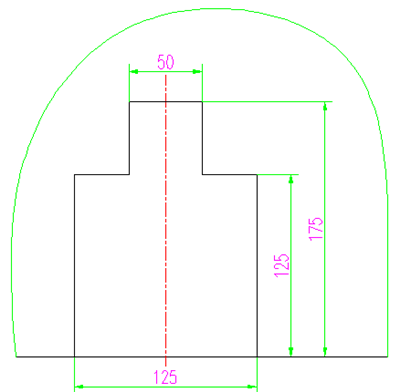

3. Cut the mounting mouth of the base of the welding claw piece on the barrel ring, evenly divided, and see Figure 2 for the specific size of the mounting mouth.

4. Solder the base of the product to the barrel using the installation tool (note: Use alkaline series electrode or CO2 gas shielded welding. Note that no bubble, slag, crack and other welding defects are allowed in the weld. Strength not less than 490MPa) multilayer weld.

5.Insert the claw piece according to the direction, install the bolt, washer and tighten.

Picture 1 Picture 2

3、Matters need attention:

1. Locate the base according to the size calculated by the above formula during welding, and the high point of the roller must be more than 10mm higher than the reinforcement, and lower the reinforcement if necessary.

2. After each positioning, teeth and claws must be fitted to measure whether the inner and outer diameters meet the requirements.

3. Before going down well, the disc moves the roller, whether the rotation is smooth and no bounce phenomenon, and whether the roller bearing clearance is reasonable.

4. When drilling, if there is no footage or slow footage, the drill pipe should be rotated by hanging, and the drill pipe should be pressurized by point dynamic every 2-3 minutes to match the cone and bottom track.

5. If there is abnormal drill pipe runout during drilling, the drill should be lifted to check the cone by 1 point.

6. Check the fastening bolts and pins after each drilling lift, and tighten them in time if they are loose.

7. When welding the base, the tooth claws must be removed, and the inner groove of the base must be filled with a working assembly to prevent the tooth sole from being loaded into the base after welding.

8. It is forbidden to use hard objects to beat the tooth (alloy tooth) when installing the tooth palm. If the tooth palm cannot be loaded into the base, the installation part of the tooth palm can be properly polished.

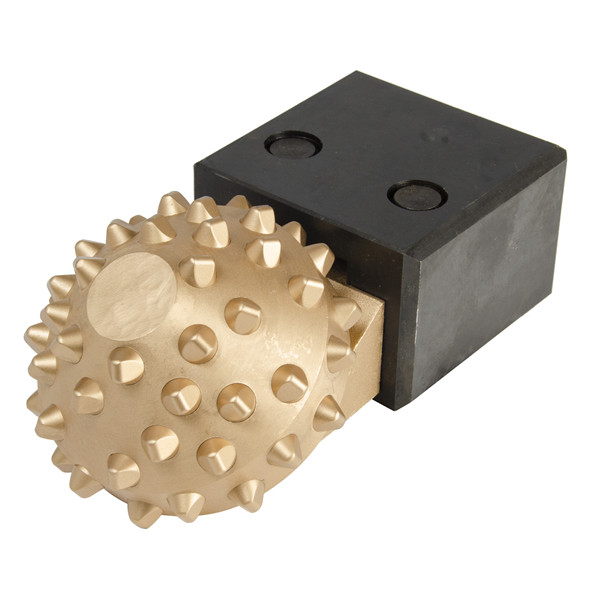

4、Structural features:

· After optimized design, the tooth layout is reasonable, and different tooth shape and tooth height are designed for all kinds of rock strata, with good drilling performance.

· The removable installation solves the problem of bearing seal being heated during welding and increases the service life of bearing.

· The base can be repeatedly installed and used to reduce welding frequency and greatly increase work efficiency.

· The bearing system is optimized for high bearing capacity and long life.

· Widely used in rotary drilling market, can achieve high drilling efficiency.